Industrial Furnace

Tank Furnace (Glass Melting Furnace)

Tank furnaces are glass melting furnaces suitable for mass production by continuous feeding of material.

The most common tank furnaces are equipped with waste heat recovery systems and produce 200 – 600 tons/day in many cases.

For planning and designing glass melting furnaces, it is necessary to consider various conditions such as the type and color of molten glass, type of products, production quantity, factory layout, and fuels used.

In addition, performance such as quality (of molten glass), fuel consumption (in operation), and life (of furnaces) must also be required. Having evaluated these items comprehensively based on our numerous accomplishments, we have been making continuous improvements, and we offer glass melting furnaces with easy maintenance and high cost performance including auxiliary systems.

Inside of a glass melting furnace

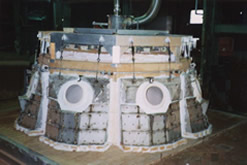

Furnace steel structure

Pot Furnace and Small Sized Tank Furnace

Pot furnaces or small sized tank furnaces can be used for small-lot production of various kinds of glass or for glass craftwork. We deliver small sized glass tank furnaces of production capacity 0.1 ton/day. For pot furnaces, we also handle a single pot furnace in which a melting pot is installed, and a joint-type pot furnace where several melting pots are heated by one heat source. In addition, we have successfully developed an energy saving pot furnace.

Single pot furnace

Inside of a single pot furnace

Joint-type pot furnace

Small sized glass tank furnace

An electric melting furnace has received attention for its energy-saving effect and improved quality. There are two types of electric melting: direct heating type where current is passed directly through the glass, and indirect heating type where the glass is heated using an electric heater. We design and construct fully-electric melting furnaces where the glass is melted only with electric power, and booster systems which is introduced to combustion tank furnaces to improve performance. The indirect heating type is often applied to pot furnaces for glass craftwork, and is evaluated as a furnace excellent in safety because it uses no fuel.

All electric melting furnace

Inside of an indirect heating-type

electric pot furnace

We have applied our accumulated, vast know-how to deliver products not only in the field of glass but also steel, nonferrous metals, and chemistry. In order to play an active part in a wide range of ceramic industries, we are always striving harder and challenging ourselves to extend our technological venture.