Waste Heat Utilization System and Waste Heat Recovery System

Recuperator (Heat Exchanger)

We design and supply recuperators.

A recuperator is a metal type heat exchanger that is used to recover heat from exhaust gases.

Depending on system conditions, it can recover tempered air of 800℃ at the maximum.

Compared with the regenerative heat recovery system, a recuperator is inferior in terms of heat recovery rate. However, it has many advantages as shown below:

- Combined use with a secondary heat recovery system such as a waste heat boiler is available.

- Initial investment can be reduced.

- Recuperators do not leak preheated air, and therefore, the air-to-fuel ratio can be controlled accurately.

- The installation area is small, and installation is therefore relatively free of normal layout limitations.

External view of a recuperator system

Cage type metallic heat exchanger

Heat recovery efficiency of our recuperators is not reduced over a long period of time, thanks to its structure that uses thermal radiation.

We have also succeeded at prolonging recuperator life by selecting special heat-resistant steel and special coating.

Cullet Preheater

We design and supply cullet preheaters.

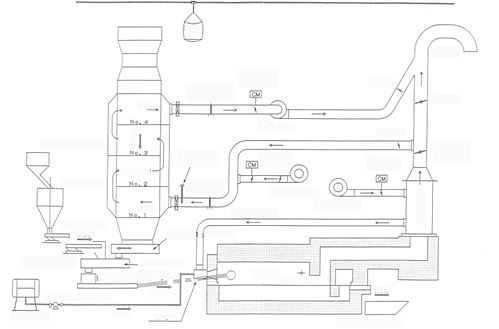

Cullet preheating flow diagram

Glass melting furnace equipped with a cullet preheater

This system recovers heat by passing high-temperature exhaust gases through cullets (material) to preheat them.

In a demonstration test furnace, we have succeeded at reducing fuel consumption by 28% with this system, in comparison with the system without cullet preheating.